- Browse Categories

- YAMAHA--- Smt Spare parts [357]

- Panasonic--- Smt Spare parts [446]

- JUKI ---Smt spare parts [225]

- Samsung---Smt Spare Parts [9]

- FUJI---Smt Spare Parts [114]

- Siemens--- Smt Spare Parts [5]

- Sony Smt Spare parts [4]

- Philip---Smt Spare parts [3]

- Mirae Smt Spare Parts [1]

- I-Pulse Smt machine spare parts [3]

- Sanyo Smt Spare Parts [6]

- AI machine parts(Auto Insertion Machines Parts) [240]

- Smt Screen Printer machine Parts [17]

- Surface Mount Parts [138]

- SMT Spare Parts [123]

- SMT Feeder [114]

- SMT Feeder Parts [22]

- SMT Nozzle [103]

- SMT PCB Board [87]

- SMT Servo Motor Driver [90]

- Printing machine parts [17]

- AI Spare Parts [98]

- Single Sided PCB Board [28]

- Double Sided PCB Board [26]

- Multilayer PCB Circuit Board [30]

- LED PCB Board [15]

- Rigid Flex PCB [31]

- PCB Printed Circuit Board [245]

- FR4 PCB Board [38]

- SMT Assembly Equipment [28]

- Smt peripheral equipment [2]

- SMT Solder Paste [12]

Sales & Support

Request A Quote

Home >

Products >

PCB Printed Circuit Board >

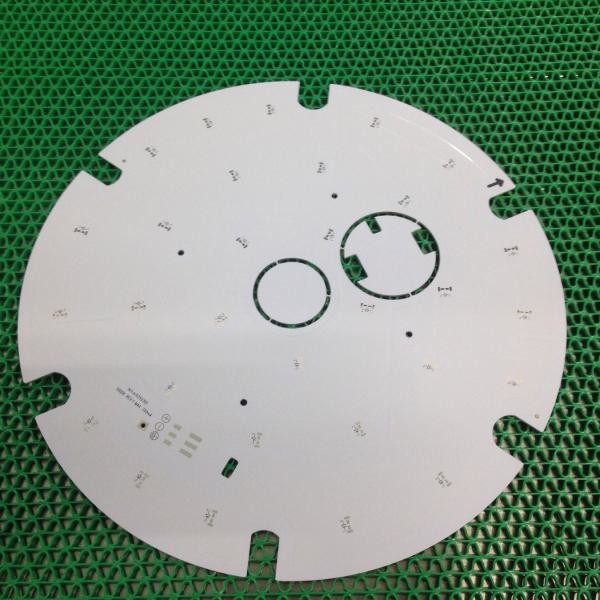

FR 1 NPTH Single Side PCB Printed Circuit Board 1.6mm Thick 1oz No Solder Mask

FR 1 NPTH Single Side PCB Printed Circuit Board 1.6mm Thick 1oz No Solder Mask

Product Details:

| Place of Origin: | China |

|---|---|

| Brand Name: | PY PCB |

| Certification: | UL,RoHs,SGS,ISO9001-2008 |

| Model Number: | No Solder Mask |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10000pcs |

|---|---|

| Price: | 1 |

Description

FR 1 Simple NPTH Single Side PCB Printed Circuit Board 1.6mm Thick 1oz No Solder Mask

Specifications

| Item | Requirement | Result | ACC | REJ | |

| Laminate | Type | FR-1 | FR-1 | √ | |

| Supplier | KB | KB | √ | ||

| Board thickness | 1.60±10% mm | 1.61-1.65 mm | √ | ||

| Outer copper foil | >=35 um | 44.17 | √ | ||

| Inner copper foil | / | / | √ | ||

| Warp-twist | <= 0.75% | 0.68% | √ | ||

| legend | Type | KUANG SHUN | KUANG SHUN | √ | |

| Color | Black | Black | √ | ||

| Location | CS | CS | √ | ||

| Marking | Co.logo | / | / | √ | |

| UL.logo | / | / | √ | ||

| Date code | / | / | √ | ||

| Marking form | / | / | √ | ||

| Location | / | / | √ | ||

| Min line width (mil) | 7.874 | 8.1 | √ | ||

| Min line spacing (mil) | 6.5 | 6.3 | √ | ||

| Min ring width (mil) | NA | NA | / | ||

| Solder Mask | Type | / | / | √ | |

| Color | / | / | √ | ||

| Thickness | / | / | √ | ||

| Pencil Test | / | / | √ | ||

| SOLVENT TEST | / | / | √ | ||

| TAPE TEST | / | / | √ | ||

| Surface treament | Lead free HASL | OK | √ | ||

| Special Treament | Silk screen | / | / | √ | |

| Location | / | / | √ | ||

| Forming | V-cut | OK | √ | ||

| Normal Testing | Electrical test | 100% PCB passed | OK | √ | |

| Visual inspection | IPC-A-600H&IPC-6012B | OK | √ | ||

| Solderability Test | 245℃ 5S 1 Cycle | OK | √ | ||

| Final inspection report | ||||||||

| Hole size and slot dimension(unit: mm, PTH tolerance +/-0.076, NPTH +/-0.05mm) | ||||||||

| NO | Required | PTH | Actual dimension | ACC | REJ | |||

| 1 | 2.050±0.05 | N | 2.050 | 2.025 | 2.075 | 2.050 | √ | |

| 2 | 3.000±0.05 | N | 3.000 | 2.975 | 3.025 | 3.000 | √ | |

| V-CUT Finish dimension (unit: mm): including | ||||||||

| NO | Required Dimension (tolerance) | Actual dimensin | ACC | REJ | ||||

| 1 | 260.99±0.15 | 261.01 | 260.89 | 261.07 | 261.10 | √ | ||

| 2 | 230.00±0.15 | 229.88 | 229.94 | 230.05 | 230.09 | √ | ||

| Reference engineering information | ||||||||

| Hole drill drawing | ACC | |||||||

| Conductor and film | ACC | |||||||

| Solder mask and film | ACC | |||||||

| Legend and film | ACC | |||||||

| Engineering changing | ACC | |||||||

| E-test Report | |||||||

| Test Type | General | Test Parameter | |||||

| Special | Test Votage | 250V | |||||

| Single mould | Test Curent | 100 m A | |||||

| Double mould | √ | Conducting Resistance | 20 M ohm | ||||

| Flying probe Test | √ | Isolated Resistance | 20 M ohm | ||||

| Test Points | 160 | All Open Test | Qualified | √ | |||

| Failure | |||||||

| The first pass Qty | 358 | All short Test | Qualified | √ | |||

| Failure | |||||||

| Reject Qty | 2 pcs | The first pass Rate | 99% | ||||

| Mian Dwfect Desciption: | |||||||

| 1 | Open Qty | 0 PCS | Repaired Qty | 0 PCS | Scrap | 0 PCS | |

| 2 | Short Qty | 0 PCS | Repaired Qty | 0 PCS | Scrap | 0 PCS | |

| 3 | Con. Defect | 0 PCS | Repaired Qty | 0 PCS | Scrap | 0 PCS | |

| 4 | Isolated Defect | 0 PCS | Repaired Qty | 0 PCS | Scrap | 0 PCS | |

| 5 | Others | 2 PCS | Repaired Qty | 0 PCS | Scrap | 2 PCS | |

| Remark: | |||||||

| Microsection Analysis Report | |||||||||||

| purpose & Req | Hole wall | Trace | |||||||||

| Copper | ≧ | 20 um | Surface copper | 35 um | |||||||

| Nickel | ≧ | 0 um | Base copper | 11 um | |||||||

| Au | ≧ | 0 um | V/X | ||||||||

| Tin/Lead | ≧ | 3.92 um | |||||||||

| Roughness | ≦ | 25 um | |||||||||

| Hole wall position Unit: um | A | B | C | D | E | F | Average | Roughness | Speciment Location | ||

| Drill | Plated | ||||||||||

| 1 | 25.600 | 24.400 | 24.460 | 26.100 | 25.380 | 25.010 | 25.158 | 21.529 | 21.629 | ||

| 2 | 24.221 | 23.021 | 23.081 | 24.721 | 24.001 | 23.631 | 23.779 | 19.327 | 19.427 | ||

| 3 | 25.513 | 24.313 | 24.373 | 23.013 | 25.293 | 24.923 | 25.071 | 17.290 | 17.390 | ||

| Trace Copper | Base Copper | Solder mask thickness | T/L THK | Ni THK | Au THK | Speciment Location | |||||

| 1 | 44.90 | 12.95 | 13.60 | 5.25 | |||||||

| 2 | 44.94 | 12.81 | 12.08 | 8.25 | |||||||

| 3 | 42.66 | 10.52 | 15.23 | 6.25 | |||||||

| Defects Inspection | |||||||||||

| Found | NO Found | ||||||||||

| 1.Plating crack | √ | ||||||||||

| 2.Resion recession | √ | ||||||||||

| 3.Plating void | √ | ||||||||||

| 4.Delamination | √ | ||||||||||

| 5.Smear | √ | ||||||||||

| 6.Copper crack | √ | ||||||||||

| 7.Blistering | √ | ||||||||||

| 8.Interconnection separation | √ | ||||||||||

| 9.Laminate void | √ | ||||||||||

| 10.wicking | √ | ||||||||||

| 11.Nail Heading | √ | ||||||||||

| Reliability Test Report | |||||||||||

| NO. | Item | Requirement | Test freqency | Test result | |||||||

| 1 | Solderability test | 245±5℃ 5sec wetting area least 95% | 1 | ACC | |||||||

| 2 | Thermal Stress | 288±5℃ 10sec, 3 cycles Check delamination Blistering,hole wall | 1 | ACC | |||||||

Contact Details

Other Products