- Browse Categories

- YAMAHA--- Smt Spare parts [357]

- Panasonic--- Smt Spare parts [446]

- JUKI ---Smt spare parts [225]

- Samsung---Smt Spare Parts [9]

- FUJI---Smt Spare Parts [114]

- Siemens--- Smt Spare Parts [5]

- Sony Smt Spare parts [4]

- Philip---Smt Spare parts [3]

- Mirae Smt Spare Parts [1]

- I-Pulse Smt machine spare parts [3]

- Sanyo Smt Spare Parts [6]

- AI machine parts(Auto Insertion Machines Parts) [240]

- Smt Screen Printer machine Parts [17]

- Surface Mount Parts [138]

- SMT Spare Parts [123]

- SMT Feeder [114]

- SMT Feeder Parts [22]

- SMT Nozzle [103]

- SMT PCB Board [87]

- SMT Servo Motor Driver [90]

- Printing machine parts [17]

- AI Spare Parts [98]

- Single Sided PCB Board [28]

- Double Sided PCB Board [26]

- Multilayer PCB Circuit Board [30]

- LED PCB Board [15]

- Rigid Flex PCB [31]

- PCB Printed Circuit Board [245]

- FR4 PCB Board [38]

- SMT Assembly Equipment [28]

- Smt peripheral equipment [2]

- SMT Solder Paste [12]

Sales & Support

Request A Quote

KIC START KIC Thermal Profiler Test , Furnace / Oven Temperature Profiler

KIC START KIC Thermal Profiler Test , Furnace / Oven Temperature Profiler

Product Details:

| Place of Origin: | Guangdong, China (Mainland) |

|---|---|

| Brand Name: | KIC |

| Model Number: | KIC STAR |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 1 |

Kic Start Thermal Profile Test Printed Circuit Boards Thermal Analyzer 6 channel Furnace Temperature Tester

1, the traditional temperature curve measurement and set has been a time consuming work, and KIC SlimKIC type 2000 temperature/time setter can solve the problem of the traditional process.

2, the operator can choose from has set a good solder paste properties database used solder paste.SlimKIC 2000 automatically set the required process or window frame.

3, if cooperate NavigatorTM after a test software, the software automatically accurate budget making process should be qualified operators can choose from has set a good solder paste properties database used solder paste.SlimKIC 2000 automatically set the required process or window frame.To reduce the repeated test requirements.Test requirements.

4, provide the PWI SlimKIC 2000, help operators understand set good process ability.Operators can decide whether to fine-tune optimization.

5, if cooperate NavigatorTM software, can automatically select the best in all possible parameter combination the set point, without artificial judgment and test and optimize.

6, if cooperate AutoFocusTM software, can be set up from past experience for you to calculate the initial process parameters.Do not need to own speculation.Software also have automatic learning function, had enough experience to once is completed after the best PWI Settings.

7, if cooperate with KIC PilotTM, for some still can automatically regulate the parameters setting of the stove, the stove without manual adjustment.

8, in complex or a large number of BGA PCBA, such as the traditional measuring 5 channels - probe is already could not meet the technical requirements.

9, KIC SlimKIC2000 provide channel 6, 9 and 12.KIC Start with 6 channels.Wave soldering, reflow soldering, general.

10, the furnace temperature tester now provides the industry's top thermometer, on software, the simulation curve function, five groups curve contrast function and on temperature measurement accuracy is not with the unparalleled in other similar brand;The host hardware, eliminating the general thermometer and heat preservation box when the temperature adjustment and separated twice cumbersome process, host directly on insulating material's heat preservation box, does not need to take out directly when measuring and read into the computer interface.

By automating the complex task of process set up the SlimKIC®2000™ makes profiling so easy that any operator can quickly achieve the optimal process. Simply select from a built-in library containing hundreds of commonly used solder paste specifications. The software uses the paste supplier's thermal profile specs to automatically define the process window. Color-coded signlas alert the operator to any out-of-specification conditions.

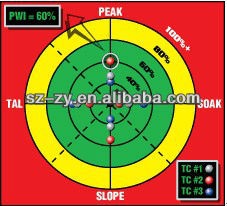

The SlimKIC 2000 simplifies profiling by reducing the process to a single number -- the Process Window Index™ (PWI) -- so you know precisely how good your profile is. The simplified user interface guides the operator through the profiling process, minimizing the potential for improper oven set up and yield-reducing defects.

The Process Window Index

Profiling Reduced to a Single Number

For precise ranking of profile performance, the KIC software uses the Process Window Index (PWI). The PWI measures the profile’s fit to the process window in a mathematical and objective manner by using a single number. This aids in optimizing the process by comparing and ranking alternative profiles in terms of their fit to the available process window. The lower the PWI, the more efficient and stable the process!

Technical Specifications

| Accuracy: | ±1.2C |

| Resolution: | Variable 0.3C to 0.1C |

| Internal Operating Temp: | 0C to 105C |

| Thermocouple Compatibility: | Type K, 9 or 12 |

| Temperature Range: | -150C to 1050C |

| Computer Capability: | PC |

| Power Requirements: | 9V alkaline battery |

| Thermal Receiver: | 433.92 MHz |

| Dimensions: | See Temperature Tolerance Chart below for specifications |

Datalogger Model: data is downloaded to the computer through a cable after the run. Dual Unit Model: data is sent to the computer in real-time during the run. It is also stored internally for high-speed download after the run.

| Temperature Tolerance Chart | (maximum endurance in minutes at specified temperature) |

| CONFIGURATION | DIMENSIONS (mm) (Length x Width x Height) | 150C | 200C | 250C | 300C | 350C | 400C |

| SlimKIC 2000, 9CH no shield | 260.4 x 79.0 x 19.9 | 8.5 | 5.5 | 4.2 | 3.5 | ||

| SlimKIC 2000, 12CH no shield | 260.4 x 99.4 x 19.9 | 8.5 | 5.5 | 4.2 | 3.5 | ||

| LowRider cover | 260.4 x 76.2 x 19.9 | 13.9 | 8.3 | 5.5 | 4.7 | ||

| Thermal Shield 1/8” (3.2mm), 9CH | 319.0 x 86.4 x 26.4 | 17.6 | 11.0 | 8.0 | 6.4 | ||

| Thermal Shield 1/8” (3.2mm), 12CH | 319.0 x 108.0 x 26.4 | 17.6 | 11.0 | 8.0 | 6.4 | ||

| LowRider and Thermal Shield 1/8” (3.2mm) | 323.9 x 86.4 x 26.4 | 22.6 | 15.1 | 10.7 | 8.7 | ||

| Thermal Shield 1/4” (6.4mm), 9CH | 330.2 x 93.0 x 34.3 | 24.6 | 15.5 | 11.5 | 9.8 | ||

| Thermal Shield 1/4” (6.4mm), 12CH | 330.2 x 115.6 x 34.3 | 24.6 | 15.5 | 11.5 | 9.8 | ||

| LowRider and Thermal Shield 1/4” (6.4mm) | 330.2 x 95.3 x 34.3 | 30.7 | 22.6 | 16.4 | 12.2 | ||

| Long Duration Thermal Shield | 381.0 x 139.7 x 76.2 | 62.8 | 42.2 | 33.1 | 29.7 | ||

| Lead-Free Thermal Shield, 9CH | 348.0 x 93.0 x 30.0 | 18.6 | 12.7 | 10.7 | 9.1 | 7.9 | 7.6 |

| Lead-Free Thermal Shield, 12CH | 348.0 x 114.0 x 30.0 | 18.6 | 12.7 | 10.7 | 9.1 | 7.9 | 7.6 |

Computer Configuation

Minimum System Requirements

800 MHz Processor/ 256 MB RAM1

2 GB available storage (for product history)

Video 1024 x 768 resolution / 16-bit

1 available USB port (for data download)

1 available parallel port or USB port (for software key options)

Microsoft® Windows® 2000, XP, Vista, or 7. (32-bit or 64-bit)