- Browse Categories

- YAMAHA--- Smt Spare parts [357]

- Panasonic--- Smt Spare parts [446]

- JUKI ---Smt spare parts [225]

- Samsung---Smt Spare Parts [9]

- FUJI---Smt Spare Parts [114]

- Siemens--- Smt Spare Parts [5]

- Sony Smt Spare parts [4]

- Philip---Smt Spare parts [3]

- Mirae Smt Spare Parts [1]

- I-Pulse Smt machine spare parts [3]

- Sanyo Smt Spare Parts [6]

- AI machine parts(Auto Insertion Machines Parts) [240]

- Smt Screen Printer machine Parts [17]

- Surface Mount Parts [138]

- SMT Spare Parts [123]

- SMT Feeder [114]

- SMT Feeder Parts [22]

- SMT Nozzle [103]

- SMT PCB Board [87]

- SMT Servo Motor Driver [90]

- Printing machine parts [17]

- AI Spare Parts [98]

- Single Sided PCB Board [28]

- Double Sided PCB Board [26]

- Multilayer PCB Circuit Board [30]

- LED PCB Board [15]

- Rigid Flex PCB [31]

- PCB Printed Circuit Board [245]

- FR4 PCB Board [38]

- SMT Assembly Equipment [28]

- Smt peripheral equipment [2]

- SMT Solder Paste [12]

Sales & Support

Request A Quote

Red Plastic SMT Solder Paste UV Curing Plastic Bonding Adhesives For Posts 30CC

Red Plastic SMT Solder Paste UV Curing Plastic Bonding Adhesives For Posts 30CC

Product Details:

| Place of Origin: | China |

|---|---|

| Brand Name: | PY |

| Model Number: | 03g |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 1 |

| Packaging Details: | Box |

| Delivery Time: | 1-7Day |

| Supply Ability: | 1000 |

Red Plastic SMT Solder Paste UV Curing Plastic Bonding Adhesives For Posts 30CC

Packaging Details

200g/bottle; 360g/bottle

A small sample for testing first is avaiable.

Delivery Time

Shipped in 5 days after payment

PY36G is one component epoxy adhesive and a kind of heat cured adhesive. It designed for stencil printing . High bonding strength, high humidity ,high intensity,excellent electrical performance and good storage stability.

Typical Usage

Mainly used for the bonding of the mounted components on SMT.

Properties Uncured

| Typical Value | Range | Test Standard | |

| Appearance | Red cream | ||

| Chemical Type | Epoxy Resin | ||

| Viscosity (Pa.s)(Brookfield RV) Spindle 7 | 200-400 | GB/T 2794-1995 | |

| Thixotropic index | 7 | ||

| Density (g/cm3) | 1.35 | 1.32-1.38 | GB/T 13354-1992 |

| Operate Time at Room Temperature (day@25°C) | 14 |

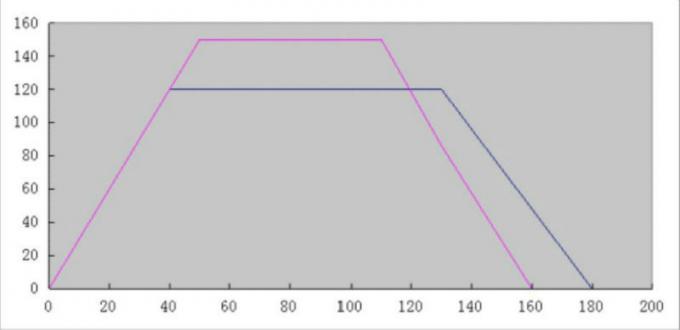

Curing Condition Recommended

90-120s at 120°C.

60-90s at 150°C

The product will obtain to higher bonding strength when higher curing temperature and longer cured time . the figure curve is the recommended curing temperature and heating rate,Underthe corresponding temperature ,components need the time when they achieve good bonding strength.

Users can set the curing furnace’s temperature parameters according to the solidified characteristic curve of the glue and the heat efficiency of the Reflow Ovens

Performance After Cured

(Cured for 30min@150°C)

Physical Property

| Typical Value | Test Standard | |

| Hardness(ShoreD) | 88 | GB/T2411-1980 |

| Shear Strength(MPa) | 18.5 | GB/T7124-1986 |

| Tg(°C)(DSC) | 105 | ASTM E1545 |

| Dielectric strength(KV/mm) | 26.8 | GB/T408.1-1999 |

| Surface resistance (Ω) | 3.5×1016 | GB/T1410-2006 |

Direction For Use

The product should be recovered to room temperature before use, don't open the aluminum foil package before recovered to room temperature(the recovering time of 300ml packaging at least 2-4 hours).

The product should be used at 25°C ,

The glue viscosity will decline under the higher temperature, which influence printing effect; High humidity can increase the glue of moisture absorption which shorten the opening hours of the glue and influence the glue bonding strength. This product opening time is 48 hours at 25 °C,55% Rh.

Suggest to print at the speed of 20-150 mm/s; Drawknife pressure is 3-4 N/cm (Afer scraping, sheet should be clean, and avoid producing wire drawing); the deviating speed from the sheet is 0.1-3.0 mm/s.

Not cured adhesive which is stick on line wires can be erased with acetone or propylene alcohol ethers.

Please seal and chill when not using up the glue.

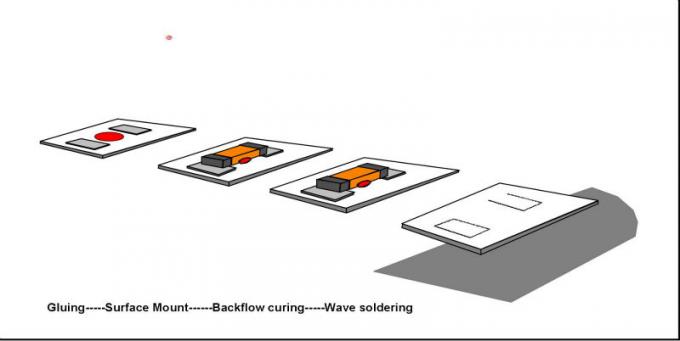

Application Process

Notice

Keep away from children.

The workshop should be adequate ventilation.

Wash with soapy water if on skin.

Wash with a lot of soapy water and then go for doctor if in eyes.

For more information, please refer to MSDS.

SMT red plastic 120-150 degree curing adhesive for posts 30CC

| Item | Parameter | curing requirement |

| Appearance | light amber to colorless and transparent liquid | |

| Fixing time | within 10s | |

| Curing tool | UV lamp/UV light | |

| Curing condition | 365 nm | |

| Multi-Part Adhesive | One- component |

Notice of Shadowless traceless fast dry UV curable glue / adhesive

1. Make sure the glass is clean and dry.

2. In order to ensure the stability of product, blow the glass surface make sure it is dry without moisture, in winter construction

3. The product is irritated to eye and skin. Thoroughly flush the eyes with water at least 20 minutes, and seek medical attention, if splashed in eyes incaution

4. Only for industrial use, please refer to instructions and Material Safety Data Sheet for health and safety