- Browse Categories

- YAMAHA--- Smt Spare parts [357]

- Panasonic--- Smt Spare parts [446]

- JUKI ---Smt spare parts [225]

- Samsung---Smt Spare Parts [9]

- FUJI---Smt Spare Parts [114]

- Siemens--- Smt Spare Parts [5]

- Sony Smt Spare parts [4]

- Philip---Smt Spare parts [3]

- Mirae Smt Spare Parts [1]

- I-Pulse Smt machine spare parts [3]

- Sanyo Smt Spare Parts [6]

- AI machine parts(Auto Insertion Machines Parts) [240]

- Smt Screen Printer machine Parts [17]

- Surface Mount Parts [138]

- SMT Spare Parts [123]

- SMT Feeder [114]

- SMT Feeder Parts [22]

- SMT Nozzle [103]

- SMT PCB Board [87]

- SMT Servo Motor Driver [90]

- Printing machine parts [17]

- AI Spare Parts [98]

- Single Sided PCB Board [28]

- Double Sided PCB Board [26]

- Multilayer PCB Circuit Board [30]

- LED PCB Board [15]

- Rigid Flex PCB [31]

- PCB Printed Circuit Board [245]

- FR4 PCB Board [38]

- SMT Assembly Equipment [28]

- Smt peripheral equipment [2]

- SMT Solder Paste [12]

Sales & Support

Request A Quote

Home >

Products >

SMT Assembly Equipment >

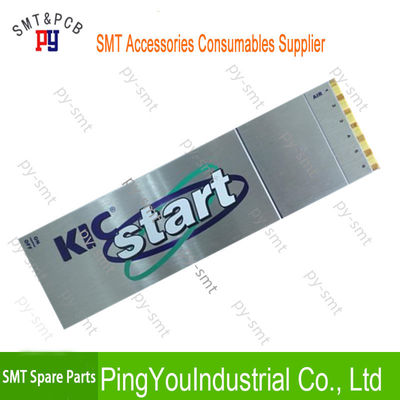

KIC Start Exceptional Value Thermal Profiler View Share Pcb Reflow Profiles On Mobile Dev

KIC Start Exceptional Value Thermal Profiler View Share Pcb Reflow Profiles On Mobile Dev

Product Details:

| Place of Origin: | Japan |

|---|---|

| Brand Name: | KIC |

| Certification: | ISO |

| Model Number: | KIC Start Exceptional |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | 1 |

| Packaging Details: | Box |

| Delivery Time: | 1 day |

| Payment Terms: | L/C, T/T |

| Supply Ability: | Long-term supply |

Description

SMT Easy to use KIC Start Exceptional Value Affordable Thermal Profiler

View and share pcb reflow profiles on mobile devices

Software Description

- Auto-Focus Power™ is a ‘recipe search engine’ with an intelligent database

- Every PCB reflow manual profile will populate the database. The correlations between the oven properties, thermal transfer rate, PCB characteristics and varying process windows enable very accurate oven setup recommendations

- In short time, the database becomes intelligent enough that a recommendation for best oven setup for any new PCB will be generated without the need to run a new pcb reflow profile

- Only input of the new PCB’s length, width and weight is required for the software to recommend the best oven recipe

Initial Oven Set Up

- A new product requires the selection of an appropriate reflow oven recipe. Manual profiling will help identify the correct setup, but to select the initial recipe requires an educated guess

- A poorly selected initial recipe runs the risk of:

- Damaging the product

- Requiring numerous profile runs before identifying the correct recipe

- The Auto-Focus Power™ recommends the initial setup without running a profile and without the need for the technician’s educated guess – within seconds.

Optimization Criteria

- Lowest energy use

- The center of the process window

- Maximum throughput

- Fastest oven changeover (or a combination of these)

Reduced Electricity Consumption

- Case studies indicate an instant 15% drop in electricity use in reflow ovens. Where do the savings come from?

- Few reflow ovens are set up with consideration for electricity consumption, so they tend to run hot and fast

- KIC’s Auto-Focus Power takes the slack out of the process by optimizing both throughput and heat/energy

Ease of Use – Ease of Results

- Process insight and expertise built into the software

- Define the process window and minimum conveyor speed – delegate the rest

- Oven set up tasks may be handled by less experienced personnel – quickly

- Less production downtime

Versatile and Low Cost Profiler

- Auto-Focus Power™ works with KIC thermal profilers.

- ·Profiler works on virtually any reflow oven on the market – old or new

- The ROI tends to be exceptionally high due to the low investment cost combined with big cost savings

- The KIC Auto-Focus and KIC Auto-Focus Power is simple, fast and easy to use, requiring minimal input or technical experience. Once the necessary criteria are provided, Auto-Focus goes to work and in seconds you are presented a suggested initial oven set up. The recipe is ranked using the Process Window Index (PWI), so you immediately know where it falls within your process specifications.

- Auto-Focus Power searches for the oven recipe with the lowest electricity use while positioning the profile in spec.

- KIC Auto-Focus includes the KIC® Navigator™ software option. KIC Auto-Focus Power includes the KIC® Navigator™ Power software option. Auto-Focus and Auto-Focus Power expand the capability and potential of the KIC software by automatically optimizing your process set up.

- Note: The KIC software may interface directly with some oven controllers, eliminating the need for manual setpoint data entry. Please consult your oven supplier for availability. The KIC software is dongle protected.

Profiling Reduced to a Single Number

The PWI measures the profile’s fit to the process window in a mathematical and objective manner by using a single number. This aids in optimizing the process by comparing and ranking alternative profiles in terms of their fit to the available process window. The lower the PWI, the more efficient and stable the process! (See the PWI data sheet for a detailed explanation)

Contact Details

Other Products